Industrial robotics is entering a new phase; one where code is written, tested and perfected in the cloud long before a bolt is tightened on the factory floor.

NVIDIA’s Omniverse platform, together with Isaac Sim and Isaac Lab, sits at the heart of this shift. By fusing high-fidelity simulation, synthetic data generation and large robot foundation models, the company promises faster time-to-market and lower total cost of ownership for anyone building physical AI solutions (NVIDIA Developer).

Figure 1 Nvidia Issac Sim Diagram: Generates synthetic data for training and fine-tuning robot foundation models, conducts software-in-the-loop testing for robot stacks, and enables robot learning through Isaac™ Lab.

From Pixels to Production

Traditional robot projects iterate slowly: design, build, test, re-build. Omniverse flips this sequence. Engineers spin up photorealistic digital twins (virtual replicas that mirror physical plant conditions) and train control policies entirely in simulation. Each sim run can proceed hundreds of times faster than real time, creating a vast library of edge-case scenarios without risking hardware damage (NVIDIA Developer).

Synthetic Data: The Hidden Multiplier

A recurring pain point in automation is the scarcity of task-specific datasets. Isaac Sim generates perfectly labeled synthetic images, depth maps and force-torque readings on demand. Because every pixel comes with ground-truth annotations, vision models start with a “clean label” advantage, reducing downstream data-cleaning budgets. Companies can also randomize lighting, textures and object shapes to harden models against real-world variability. This simulation-to-real (sim2real) pipeline trims months off annotation schedules and slashes data-collection costs (NVIDIA).

Foundation Models Meet Digital Twins

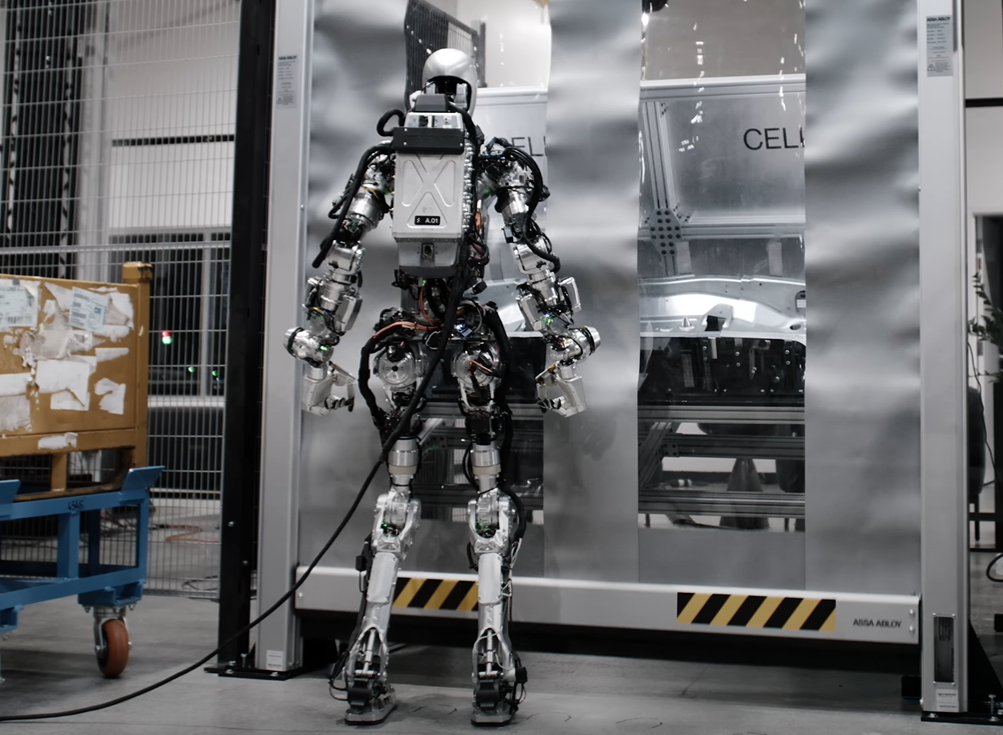

Project GR00T and the GrootN1 foundation model extend the large-model paradigm to robotics. Pre-trained on diverse simulated motions, GrootN1 can be fine-tuned for plant-specific pick-and-place jobs with far less training data than bespoke controllers need. The model’s generalist capabilities (locomotion, manipulation, whole-body control) are all stress-tested inside Isaac Lab before a single servo spins. Humanoid or not, the same software stack lets manufacturers repurpose skills across product lines, protecting R-and-D investments (NVIDIA Developer).

Figure 2 NVIDIA Cosmos™ simulation of an industrial environment, illustrating how generative world models enable autonomous robots and physical AI development.

Cross-Industry Evidence

- Automotive: BMW uses Omniverse to map entire vehicle plants, identifying material-flow bottlenecks virtually and fixing them before concrete is poured. Early studies report double-digit percentage reductions in design re-work [5](WIRED).

- Logistics: Third-party integrators combine Isaac Sim with AWS RoboMaker to rehearse swarm-robot navigation in synthetic warehouses, hitting safety certification milestones 30 % faster than purely physical trials.

- Healthcare: Med-tech startups simulate delicate end-of-arm tooling for surgical assistance, avoiding costly cadaver labs until models achieve baseline dexterity scores.

These successes reveal a common pattern: front-loading simulation compresses the traditionally long “debug in hardware” phase, freeing capital for additional product lines or geographic expansion.

Time-to-Value and Cost Calculus

NVIDIA estimates that physics-correct simulation can accelerate development timelines by a factor of 5–10 while cutting validation costs up to 40 %. Even conservative ROI models show break-even within the first production year when digital-twin investment displaces extensive physical prototyping.

The Future Belongs to Simulation-First Robotics

A decade ago, “train in simulation, deploy in hours” sounded like science fiction. Today it is a board-level strategy. By merging scalable compute, photorealism and foundation models, NVIDIA’s simulation-first approach converts robotics from a bespoke engineering adventure into a repeatable software workflow. The winners will be firms that treat their digital twin as living infrastructure—updating it as obsessively as DevOps teams update code. For them, the line between virtual and physical manufacturing will continue to blur—along with the competitive advantage of being first to automate.

Sources

- NVIDIA Developer, “Isaac Sim – Robotics Simulation and Synthetic Data Generation,” accessed 14 Jul 2025. (NVIDIA Developer)

- NVIDIA Use Case, “Synthetic Data for AI & 3D Simulation Workflows,” accessed 14 Jul 2025. (NVIDIA)

- NVIDIA Developer Blog, “Advancing Humanoid Robot Sight and Skill Development with Project GR00T,” Nov 2024 . (NVIDIA Developer)

- WIRED, “The Industrial Metaverse Is Keeping the Dream Alive,” May 2025. (WIRED)

- The Robot Report, “AWS Offers Accelerated Robotics Simulation with NVIDIA,” Dec 2024. (therobotreport.com)

- Robotics 24/7, “Flexiv, NVIDIA Bring High-Fidelity Force Control to Robotic Simulation,” Jul 2025. (robotics247.com)

- Training In Simulation Using NVIDIA Isaac Lab