Against backdrops, automation and robotics are emerging not as speculative technologies of the future but as pragmatic tools for transforming the way homes are built today. This shift is not only about machinery; it’s about redefining workflows, minimizing inefficiencies, and restoring viability to a segment of the economy long overdue for innovation.

Featured picture Source: FBR Hadrian® , a construction robot, capable of building structural, load-bearing walls of a brick/block house in as little as a day., Hadrian®: Automated Construction Robot from FBR

Reinventing Homebuilding with Robotics

Automation in construction, particularly in residential buildings, offers a path to significantly reducing costs, accelerating timelines, and improving quality. One case demonstrates that a full home structure was delivered in 48 days; from demolishing an existing garage to delivering an occupiable structure. Current operational models aim to reduce this cycle to under 30 days for future builds. This kind of turnaround is only possible through a highly coordinated and scalable construction approach, in which up to 85% of the work is done offsite in controlled factory environments.

Where Automation Is Delivering Value in Homebuilding

BIM-to-Field Layout & Overhead Drilling.

Layout robots print full-size BIM plans directly on the slab, so trades start from a single source of truth.

Figure 1Dusty Robotics’ FieldPrinter prints digital designs directly onto the jobsite floor, enabling automated layout and efficient BIM-to-field workflows.

Semi-autonomous drilling systems then execute high-volume, overhead anchor patterns for MEP supports.

Figure 2 HILTI Jaibot semi-autonomous drilling robot is taking roof and wall installation work to the next level achieving significant productivity increases.

Drywall, Plastering & Painting.

Finishing robots are compressing schedules and improving ergonomics.

Figure 3 Canvas’s 1200CX system reportedly cuts the typical mud-and-sand workflow from about five days to two.

Rebar Tying & Heavy Placement.

Figure 4 Advanced Construction Robotics’ TyBOT autonomously ties intersections (advertised 99% accuracy), while IronBOT lifts and places up to 5,000-lb rebar bundles, shifting crews to higher-skill tasks and reducing strain injuries.

Excavation & Trenching.

Autonomy is entering sitework:

Figure 5 Built Robotics retrofits excavators for fully autonomous trenching, common in utility runs for residential communities, aiming to cut rework and keep operators out of harm’s way.

3D-Printed Homes & Components.

Concrete-printing systems are moving from pilots to production.

Figure 6 The BOD2 printer from COBOD completed Europe’s largest printed building, signaling industrial-scale maturity of the method.

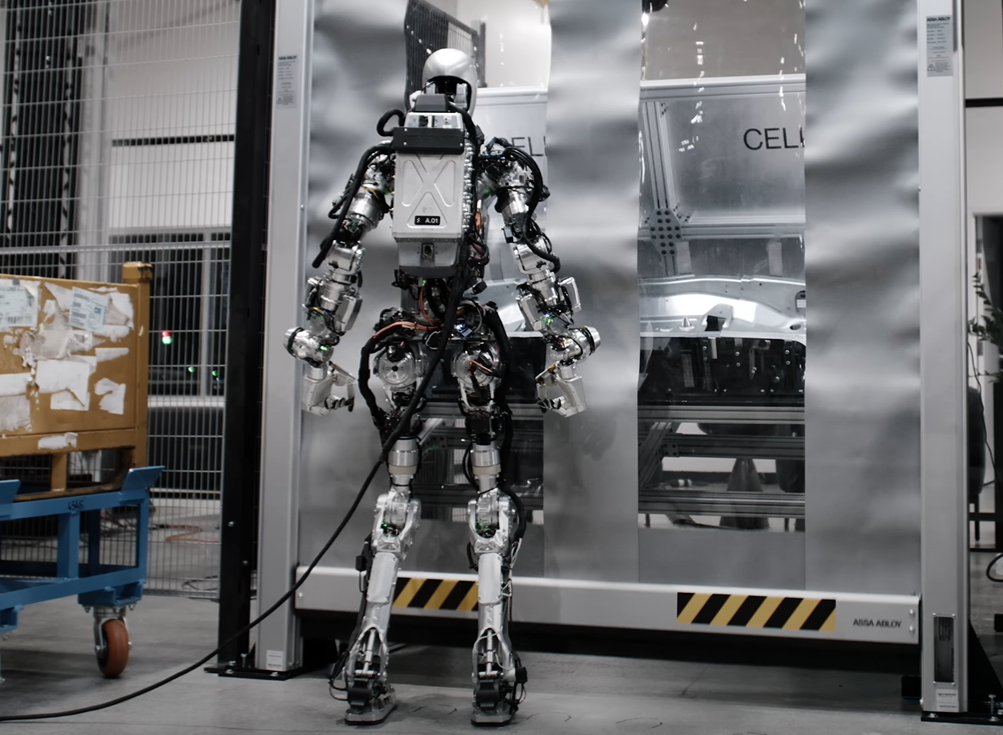

Robotized Off-Site Manufacturing.

Figure 7 – Japanese leaders like Sekisui House run robot-equipped lines from Kawasaki Robotics that fabricate custom housing components/modules at quality levels hard to match on sites.

Cell-based robotics are used for automated wall assembly. This off-site model underpins faster, cleaner neighborhood build-outs. By relocating most of the construction indoors, the process minimizes weather-related delays and safety hazards. Secondly, job sites become dramatically quieter and cleaner, improving community relations and reducing disruption.

Figure 8 Reframe’s offsite manufacturing reduces expenses, shortens construction time, and streamlines the building process. Utilizing microfactories, homes are produced with consistent quality, remain within budget, and can be made ready for occupancy more quickly than with traditional methods.

In a recent case at Reframe Systems, Vikas Enti noted that a food truck generator, not the crane, was the loudest part, showing how low industrial noise can be. [Source: Reframe Systems]

Tackling Labor Shortage Through Automation

Construction faces a massive labor gap: According to an analysis of data from the U.S. Census Bureau, it was estimated a shortfall of 500,000 workers (in the US), with 40% of skilled trades expected to retire within the next decade. This reality presents a structural challenge that traditional hiring and training pipelines cannot fill quickly enough. Automation offers a lever to counterbalance these pressures, not by replacing humans, but by amplifying their productivity.

By automating repetitive and physically demanding tasks (such as wall framing or component alignment) human workers can be reallocated to roles requiring precision, creativity, or client interaction. These higher-value tasks not only align better with craftsmanship but also enhance job satisfaction. Additionally, apprenticeship programs benefit from technology-enriched workflows, where assembly instructions resemble intuitive visual guides more than technical blueprints. As a result, less experienced workers can reach productivity levels on par with seasoned tradespeople.

Driving Efficiency with Robotic Precision

Beyond productivity, automation introduces a layer of predictability rarely found in traditional construction. Industrial robotics operate with precision and consistency, removing variability that often leads to delays or budget overruns. In the new world of robotics, robots no longer need to rely on pre-programmed paths. Instead, they adapt in real-time, recalculating motion plans based on sensor inputs and material positioning. This flexibility reduces the need for tight tolerances in material feed or manual corrections.

Moreover, the integration of vision systems allows for bulk material processing, a departure from the conventional approach that depends on fixed orientations and guided placements. This technology enables the deployment of scalable micro-factories and supports the reshoring of construction-related manufacturing. With mobile or stationary robotic units capable of framing, sanding, or painting on-site components, the barrier to adopting advanced techniques in smaller or decentralized locations diminishes.

Evolving Human Roles in the Age of Automation

The notion that automation threatens jobs overlooks a key economic principle: increasing labor productivity often leads to job transformation, not elimination. Traditional roles may evolve, but the need for human oversight, judgment, and skill remains integral to the process. In this paradigm, human labor is repositioned to supervise, refine, and finalize construction work that automation cannot fully replicate; particularly tasks involving finishes, trim, or site-specific adjustments.

Importantly, this model supports higher wages. When individuals can do more in less time, their economic value increases, justifying better compensation. It also creates a safer, cleaner, and more stimulating working environment; attributes that can attract younger generations to the industry.

Shaping the Future of Construction

By creating modular, repeatable systems, construction can transition from bespoke, labor-intensive processes to scalable manufacturing models. This change parallels transformations seen in other industries, where digitization and automation led to higher output, better quality, and lower costs.

In this context, automation is not an option but a necessity. As population grows and climate resilience demands more sustainable and affordable housing, the current methods fall short. Without an increase in efficiency, the industry will not meet future demand. Robotic construction (through factory-built components, predictive workflows, and software-defined execution) presents a credible and replicable model for addressing this crisis.

Sources

- U.S. skilled labor shortage in construction: 500,000 workers, with 40% retiring in 10 years [“Associated Builders and Contractors”, Feb-2024, https://www.abc.org/News-Media/News-Releases/entryid/19965]

- Episode 103 – Vikas Enti, CEO and Co-Founder of Reframe Systems – YouTube

- Manufacturing Matters

- Reframe Systems | Home Builders | Resilient, Predictable Construction