The frontline reveals four trends that are reshaping factories worldwide:

- Mobile robotics,

- Ai-driven perception,

- Cybersecurity-by-design and

- Hyper-flexible equipment

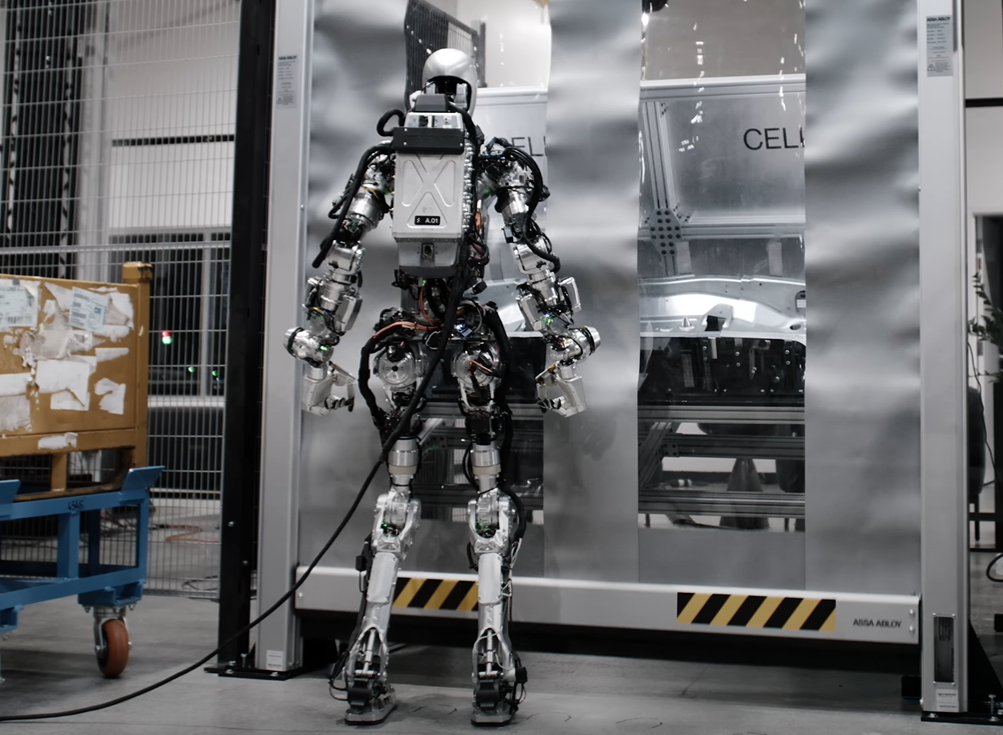

How Mobile Robots Are Transforming Manufacturing.

Autonomous Mobile Robots (AMRs) first proved their worth by ferrying pallets through fulfilment centers; now they are rolling into machining aisles and assembly cells. AMRs let manufacturers decouple material flow from fixed conveyors, making layout changes far easier when product mixes shift. Market analysts value the AMR sector at US $ 4.07 billion in 2024 and project a 15.1 % compound annual growth rate through 2030 (1). AMRs are exploding in warehouse space and starting to penetrate factories, adding that smaller plants see them as an affordable first step toward lights-out logistics.

AI-Powered Perception Is Unlocking True Production Flexibility

Early flexible cells could toggle between two-part numbers; new ones recognize hundreds. Cells can now identify each incoming component by camera, adjust tooling on the fly and route data to quality dashboards. This leap comes from combining high-resolution machine vision with deep-learning models trained on vast image sets, letting robots cope with variable orientation, mixed bins or imperfect labels.

Enterprise adoption is still experimental; A survey results show that many projects are pilots rather than plant-wide rollouts. Yet global AI spending is accelerating: one industry study foresees outlays reaching US $ 632 billion by 2028 (2) (my.idc.com). Management teams now mandate AI trials, much as they once mandated collaborative robots, pushing engineering groups to find practical use cases.

Cybersecurity-by-Design: A New Default for Industrial Automation

Digital production creates torrents of sensor data; every connected controller becomes a potential attack surface. The customers are “asking for deeper involvement in the cybersecurity aspects,” driven largely by new European rules that require any control device capable of internet connection to include security features. The EU’s Horizontal Cybersecurity Regulation for products with digital elements, taking full effect in 2025, formalizes this shift (3).

Practically, that means encrypted protocols, authenticated firmware updates and rigorous segmentation between operational-technology (OT) and information-technology (IT) networks. Integrators must specify firewalls and zero-trust gateways alongside robots and grippers; an added cost but also a prerequisite for cloud-driven analytics.

Flexible Automation as a Strategic Shield Against Market Volatility

Flexibility is not limited to tooling; it is a risk-mitigation philosophy. The unexpected 10% tariffs on in-transit components mean that only financial resilience and operational agility offer realistic protection.

Concrete measures include:

- Batch-size-one capability. Quick-change end effectors and software recipe management cut change-over time from hours to seconds.

- Modular layouts. AMRs, quick-disconnect utilities and plug-and-play safety scanners let cells be rearranged during scheduled downtime.

- Repurposing legacy assets. Engineering-services teams increasingly spend months retasking idle robots rather than ordering new ones, faster and cheaper during component shortages.

Data underline why this matters: roughly 40 % of all new U.S. industrial robots in 2024 still went into automotive plants, but growth outside that sector is now neck-and-neck (4). As product variance balloons (EV platforms, personalized consumer goods, seasonal medical devices) manufacturers that lock into a single model risk stranded assets.

Flexibility Is the New Foundation for Manufacturing Resilience

Mobile platforms, AI perception, built-in cybersecurity and modular equipment are converging to make flexible automation attainable for companies far smaller than the traditional automotive giants. Yet technology is only half the equation; financial buffers, continuous up-skilling and a willingness to experiment complete the resilience package. Factories must remain agile to keep up with constant disruption.

Sources

1 | Global AMR market valued at US $ 4.07 bn (2024) with 15.1 % CAGR 2025-30 | Grand View Research, Apr-2025 (Grand View Research) |

2 | Worldwide AI spending forecast to reach US $ 632 bn by 2028 | IDC Press Release, Sep-2024 (my.idc.com) |

3 | EU regulation mandates cybersecurity for all connected control devices from 2025 | EUR-Lex summary of Horizontal Cybersecurity Requirements, Jan-2025 (EUR-Lex) |

4 | About 40 % of new U.S. robot installations in 2024 were automotive | International Robotics Federation press note, May-2025 (roboticsandautomationmagazine.co.uk) |