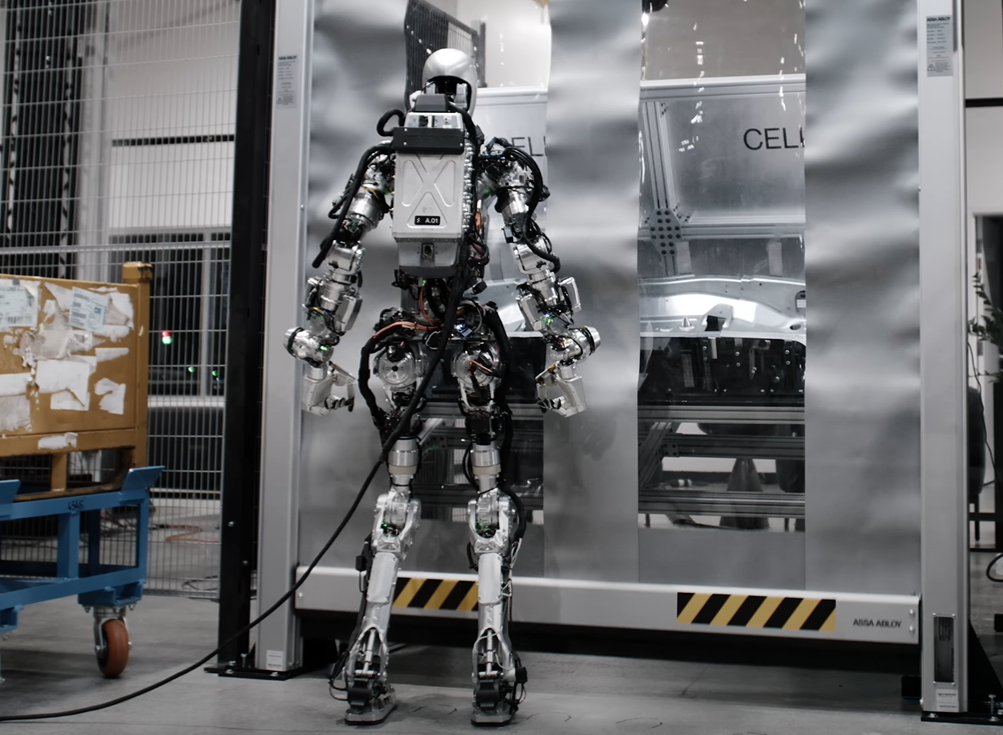

Even Tesla’s humanoid robot Optimus recently encountered production problems, making it hard to meet its yearly target. [The Humanoid Hub].

Why Manufacturing Is So Complex?

Moving from lab to factory is not a straight path. It introduces:- Supply chain risks: Dependence on global suppliers means exposure to geopolitical shifts, shipping delays, and shortages. The recent semiconductor crisis showed how fragile even the largest players can be [McKinsey].

- Yield issues: A prototype may work, but ensuring every unit on a line meets spec is another story. Even Apple, famous for operations excellence, faced yield challenges when scaling Face ID modules in the iPhone X [Bloomberg].

- Quality control: Defects multiply quickly when processes are scaled. A single overlooked tolerance can turn into thousands of defective units.

Lessons From the Field

Jeffrey Bussgang reminds in Mastering the VC Game that investors back teams who can execute beyond the prototype phase, because productization is often where startups stumble. Hardware founders must demonstrate not only innovation but also operational excellence.Established companies often miss disruptive opportunities because they optimize for efficiency instead of exploring new manufacturing approaches. Startups must avoid that trap; agility is their edge.

If the challenge is too big for the skillset of the team and there is no time to scale up, hiring a contract manufacturer is a good way to mitigate the risks of failure.

How Startups Can De-Risk Scaling

Here are three practical levers:- Design for Manufacturability Early: Eric Ries in Lean Startup stresses testing assumptions fast. The same applies to hardware; don’t wait until production to test tolerances and assembly methods.

- Build Supply Chain Resilience: Diversify suppliers and plan for redundancy.

- Invest in Quality Assurance (QA) Systems: Data-driven quality monitoring reduces costly recalls. Toyota’s lean production system remains a gold standard, with its “andon cord” philosophy empowering workers to stop a line if quality is compromised [Harvard Business Review].

Scaling hardware isn’t glamorous; it’s grueling. But those who master the transition from prototype to production unlock defensible moats and investor confidence.